Design for Disassembly: How Fastener Choice Impacts the Recyclability of Consumer Electronics and Automotive Batteries

1. Introduction

The global transition from a linear, take-make-dispose economy to a circular, closed-loop system is one of the defining industrial imperatives of the modern era. As the proliferation of consumer electronics and the mass adoption of electric vehicles accelerate, the world faces an unprecedented accumulation of complex, multi-material end-of-life products. While significant engineering focus has been placed on improving the performance, energy density, and aesthetic appeal of these technologies, the end-of-life management of these devices is frequently treated as an afterthought. The critical bottleneck in the recycling pipeline is not necessarily the chemical extraction of valuable materials, but rather the physical act of disassembly. The feasibility, safety, and economics of disassembly are almost entirely governed by a singular design choice: the fasteners used to hold the product together.

Fasteners, broadly defined to include mechanical components like screws, bolts, and clips, as well as chemical bonding agents like adhesives and welds, are the fundamental gatekeepers of the circular economy. If a product cannot be dismantled efficiently and safely, its constituent materials cannot be isolated, purified, and reused. This white paper delves into the principles of Design for Disassembly, analyzing the profound impact that fastener selection has on the recyclability of two highly complex product categories: consumer electronics and automotive electric vehicle batteries. By examining the engineering trade-offs between permanent adhesion and reversible mechanical fastening, this paper illuminates the path toward a truly sustainable manufacturing paradigm.

2. The Core Principles of Design for Disassembly

Design for Disassembly is an engineering and manufacturing philosophy that explicitly targets the end-of-life phase of a product. Its primary objective is to facilitate the easy, rapid, and cost-effective separation of a product into its constituent materials and components. To achieve this, engineers must adhere to several fundamental principles, all of which are directly or indirectly influenced by joining technologies.

First, material homogeneity is crucial. Products composed of fewer, more uniform materials are inherently easier to recycle. However, modern electronics and batteries are inherently heterogeneous, requiring the bonding of metals, plastics, and composites. The method used to bond these disparate materials determines whether they can be separated later. Second, modularity involves breaking down a product into discrete, self-contained units that can be independently accessed and removed. A highly modular design is rendered useless if the modules are permanently welded together.

Third, and most critical to this analysis, is simplified and reversible fastening. Design for Disassembly heavily favors reversible fasteners, such as screws, snap-fits, and clips, over permanent joining techniques like adhesives, ultrasonic welding, and rivets. Reversible connections allow for non-destructive disassembly, which preserves the structural integrity of the components for potential reuse, refurbishment, or direct recycling. Furthermore, accessibility ensures that these fasteners can be easily reached and manipulated by human operators or automated robotic systems using standard tools. When components are glued together or when screws are hidden behind glued panels, accessibility is compromised, and the disassembly process devolves into destructive shredding.

3. Consumer Electronics: The Miniaturization and Adhesion Conundrum

The consumer electronics industry, encompassing smartphones, laptops, tablets, and wearable devices, has been driven by an relentless pursuit of miniaturization, sleek aesthetics, and environmental durability. Consumers demand devices that are razor-thin, lightweight, and capable of withstanding submersion in water or exposure to dust. To achieve these stringent design requirements, manufacturers have systematically replaced traditional mechanical fasteners with advanced adhesives, double-sided tapes, and chemical bonding agents.

Adhesives offer compelling advantages during the primary lifecycle of an electronic device. They consume virtually no physical volume, allowing for tighter component packing. They distribute mechanical stress evenly across surfaces, reducing the risk of point-failure during drops. Crucially, they act as impenetrable seals, enabling the high ingress protection ratings expected of modern mobile devices. However, these same properties make end-of-life disassembly a costly and environmentally damaging nightmare.

When an electronic device is sealed with high-strength adhesives, non-destructive manual disassembly becomes exceptionally difficult. Repair technicians and recyclers must apply precise amounts of thermal energy and chemical solvents to weaken the adhesive bonds without damaging the delicate lithium-ion batteries or sensitive logic boards contained within. This process is highly labor-intensive, hazardous, and economically unviable at a massive scale. Consequently, the default recycling method for heavily glued electronics is often destructive mechanical shredding.

Shredding a device without prior separation of its components leads to catastrophic material mixing. Adhesives remain attached to plastic and metal fragments, acting as contaminants in the recycling stream. When plastic casings are shredded while still coated in paint or bonded to incompatible polymers, the resulting recycled plastic suffers a massive degradation in mechanical properties. Studies have shown that remaining coating impurities can reduce the impact resistance of recycled plastics by significant margins, rendering them unsuitable for high-performance applications and relegating them to low-value downcycling. Furthermore, the smelting of mixed electronic waste results in the complete loss of highly valuable, energy-intensive plastics and volatile rare earth elements.

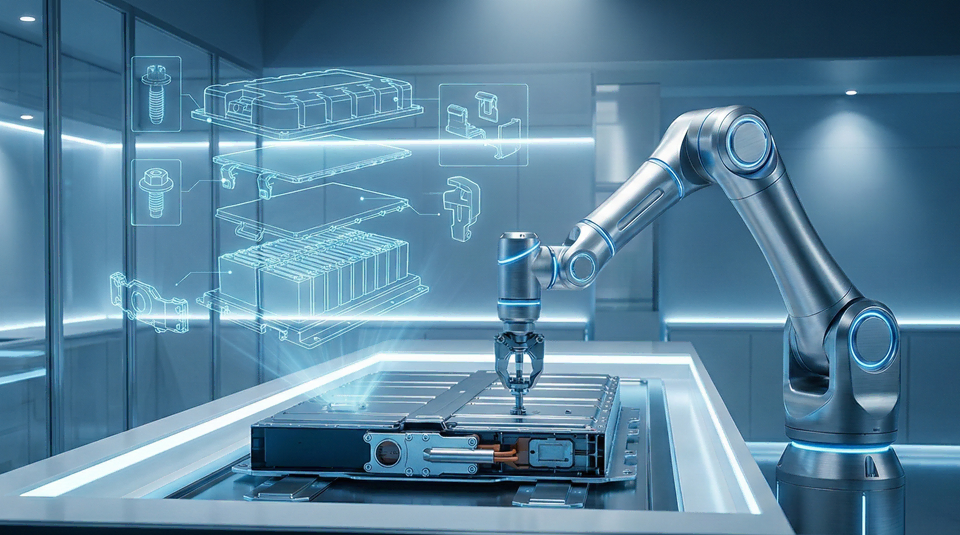

4. Innovations in Electronic Disassembly: Robotics and Snap-Fits

To reconcile the need for high-throughput recycling with the demand for material purity, the electronics industry is increasingly exploring automated robotic disassembly. General-purpose robots, equipped with advanced computer vision and machine learning algorithms, hold the potential to dismantle devices at a speed and scale that human labor cannot match. However, robots require a high degree of predictability. The force required to break a glued joint is highly variable and unpredictable, often resulting in shattered glass, bent frames, or ruptured batteries when a robot attempts to pry a device apart.

To enable robotic disassembly, a paradigm shift in fastener selection is required. Mechanical snap-fits, particularly cantilever snap-fits, are emerging as a superior alternative for Design for Disassembly. A cantilever snap-fit features a flexible beam that deflects during assembly to secure components and can be easily depressed by a robotic effector to release them. This allows for repeated, predictable, and non-destructive engagement.

Standardized micro-screws also play a vital role. While they require threaded inserts and consume more physical space than adhesives, screws provide a highly reliable and reversible connection. When electronic devices are designed with exposed, standardized screw heads, robotic systems can utilize specialized screwdriving end-effectors to rapidly unfasten the casing, liberating the logic boards, batteries, and screens for targeted, high-value recovery.

5. Automotive EV Batteries: A Monumental Fastening Challenge

While consumer electronics present a challenge of miniaturization, automotive electric vehicle batteries present a challenge of massive scale, extreme thermal dynamics, and critical safety requirements. An electric vehicle battery is not merely an energy storage device; in modern architectures, it is a fundamental structural component of the vehicle chassis. It must withstand immense dynamic loads, high-frequency vibrations, and catastrophic impact forces, all while managing the intense heat generated during rapid charging and discharging cycles.

An electric vehicle battery pack is typically constructed in a hierarchical structure: individual electrochemical cells are grouped into modules, and these modules are assembled into the final pack. The fastening techniques used at each level of this hierarchy dictate the ultimate recyclability of the vehicle.

Currently, the automotive industry relies heavily on structural adhesives, polyurethanes, and epoxies for battery assembly. Adhesives are utilized to bond cells to cooling plates, to secure modules within the battery tray, and to seal the upper lid of the battery enclosure. Furthermore, Thermal Interface Materials are heavily applied between cells and cooling systems. Many of these thermal materials cure into rigid, highly adhesive structures.

6. The Engineering Trade-offs of EV Battery Adhesives

The preference for adhesives in electric vehicle manufacturing is rooted in compelling engineering logic. Mechanical fasteners, such as steel bolts and rivets, add significant mass to the vehicle. In the context of electric mobility, every additional kilogram reduces the driving range and overall energy efficiency of the vehicle. Adhesives eliminate the need for heavy metal hardware, contributing directly to vehicle lightweighting.

Furthermore, adhesives provide continuous load transfer across broad surface areas. Unlike a bolt, which creates a point of concentrated stress that can lead to metal fatigue over time, a structural adhesive distributes the stress of driving vibrations evenly across the battery housing. This is particularly crucial in cell-to-pack designs, where the intermediate module housing is eliminated to save weight, and individual cells are bonded directly to the vehicle chassis using structural foam and heavy-duty resins.

However, from a circular economy perspective, the widespread use of structural adhesives in battery packs is disastrous. Electric vehicle batteries contain highly valuable critical minerals, including lithium, cobalt, nickel, and copper. To recover these materials with maximum efficiency, the battery pack must be carefully dismantled down to the cell level. Structural adhesives make this nearly impossible. Attempting to pry apart modules bonded with high-strength epoxy often results in puncturing the cell casing. A punctured lithium-ion cell exposed to oxygen and moisture poses an immediate and severe risk of thermal runaway, toxic gas emission, and explosive fire.

Because non-destructive disassembly is prohibitively dangerous and time-consuming for glued battery packs, recyclers are forced to employ destructive techniques. The entire battery pack or module is often fed into a massive industrial shredder under an inert atmosphere or submerged in a liquid solution. The resulting shredded output, known as black mass, must then undergo complex, energy-intensive hydrometallurgical or pyrometallurgical processing to extract the elemental metals. This destructive pathway completely destroys the highly engineered structures of the battery, including the aluminum housings, copper busbars, and intact cathode crystal structures, resulting in a massive loss of embedded energy and economic value.

7. Mechanical Fasteners in EV Design: Enabling the Circular Loop

To enable safe, non-destructive disassembly and high-value material recovery, electric vehicle manufacturers must pivot toward mechanical fastening systems optimized for Design for Disassembly. Mechanical fasteners allow for the clean separation of battery components, enabling direct recycling methods where cathode materials are recovered and regenerated without being reduced to their elemental state, or allowing for the reuse of healthy cells in second-life grid storage applications.

Designing for mechanical fastening in a high-voltage, high-vibration environment requires sophisticated hardware. Standard automotive bolts are insufficient, as they may loosen under continuous vibration or fail under severe thermal cycling. Specialized fastening solutions include the following:

- Screw and Washer Assemblies: These fasteners integrate a conical washer directly onto the screw. In the high-voltage busbar connections of a battery, temperature fluctuations cause materials to expand and contract, which can lead to a loss of clamping force. The conical washer acts as a spring, compensating for material compression and maintaining a secure electrical connection without relying on permanent thread-locking glues.

- Clinching Fasteners and Threaded Inserts: Because electric vehicle battery trays are often constructed from thin, lightweight aluminum alloys to save weight, standard tapped threads are prone to stripping. Clinching nuts are pressed directly into the thin sheet metal, providing a highly durable, reinforced thread that allows for repeated fastening and unfastening of the battery lid without degrading the host material.

- High-Tensile Steel Bolts: Used for the primary structural mounting of the battery pack to the vehicle frame, these bolts provide the massive shear and tensile strength required for crash safety. To mitigate the risk of galvanic corrosion when paired with aluminum housings, these bolts must be treated with specialized zinc-flake coatings.

While mechanical fasteners enable circularity, they impose significant engineering constraints. They consume physical space, slightly reducing the volumetric energy density of the battery pack. They add weight, and they require the integration of separate rubber gaskets or elastomer seals to protect the battery internals from moisture and debris, whereas adhesives perform bonding and sealing simultaneously. Balancing these trade-offs is the central challenge of modern sustainable automotive engineering.

8. Comparative Analysis: Permanent Adhesion vs. Reversible Fastening

To clearly delineate the impact of fastener choice on the end-of-life ecosystem, it is necessary to compare the outcomes of permanent adhesion versus reversible mechanical fastening across multiple dimensions.

| Evaluation Metric | Permanent Adhesives and Welding | Reversible Mechanical Fasteners |

|---|---|---|

| Manufacturing Speed and Automation | Extremely high. Liquid adhesives can be rapidly dispensed by robotic arms, and curing can be accelerated with heat. | Moderate. Requires precise alignment, torque control, and physical insertion of hardware. |

| Weight and Energy Density | Optimal. Adds minimal mass, allowing for the highest possible vehicle range or thinnest electronic device profile. | Sub-optimal. Metallic hardware adds physical weight and requires internal volume for threaded inserts and tool clearance. |

| Non-Destructive Disassembly | Nearly impossible. Separation requires excessive force, chemical solvents, or extreme heat, frequently destroying the host components. | Highly feasible. Components can be cleanly unfastened using standard tooling, preserving structural and functional integrity. |

| Material Stream Purity | Low. Adhesives contaminate shredded plastic and metal streams, severely degrading the mechanical properties of recycled materials. | High. Components are segregated cleanly prior to processing, yielding high-purity recycled polymers and unalloyed metals. |

| Second-Life and Remanufacturing | Prevented. Devices and battery modules cannot be safely refurbished if internal access requires destructive entry. | Enabled. Intact battery modules can be repurposed for grid storage, and logic boards can be harvested for component reuse. |

9. Future Frontiers in Fastener Technology

The tension between the performance benefits of adhesives and the recyclability benefits of mechanical fasteners is driving rapid innovation in joining technologies. The future of Design for Disassembly lies in hybrid solutions that offer the best of both paradigms.

One of the most promising areas of research is the development of active debonding adhesives. These are structural adhesives engineered to provide immense strength during the product’s operational life, but which can be commanded to release their bond upon exposure to a specific, controlled trigger. Researchers are developing adhesives embedded with thermal expansion microcapsules that permanently shatter the adhesive matrix when heated beyond a specific threshold. Other formulations are designed to rapidly depolymerize when exposed to specific wavelengths of ultraviolet light or when a specific electrical voltage is applied across the bond line. If commercialized at scale, debonding adhesives would allow manufacturers to maintain the lightweighting and sealing benefits of glue while enabling the rapid, clean disassembly associated with screws.

In the realm of mechanical fastening, the integration of digital technology is creating smart fasteners. These fasteners are manufactured with embedded micro-sensors capable of monitoring the tension and structural integrity of the joint in real-time, alerting the vehicle’s management system to potential failures. For recycling purposes, fasteners are being etched with microscopic data matrices or QR codes. When an end-of-life battery pack enters a recycling facility, automated optical scanners can read these codes on the fasteners, instantly retrieving a digital twin of the battery that details the exact torque specifications required for removal, the material composition of the surrounding components, and the optimal disassembly sequence.

Furthermore, the fasteners themselves are becoming part of the circular economy. The production of virgin steel and aluminum for bolts and screws is highly energy-intensive. A growing industry trend involves manufacturing high-performance fasteners from post-consumer recycled metals. Producing steel fasteners from recycled scrap utilizes significantly less energy and drastically reduces greenhouse gas emissions compared to virgin ore processing. By utilizing recycled fasteners to assemble products designed for disassembly, manufacturers close the loop on multiple levels simultaneously.

10. The Regulatory and Economic Imperative

The shift toward Design for Disassembly and the reevaluation of fastener choices is not occurring in a vacuum; it is being aggressively accelerated by shifting global regulations and fundamental resource economics. Legislative frameworks are increasingly penalizing the linear production model and mandating circularity.

In the European Union, comprehensive legislation such as the Circular Economy Action Plan and the updated Battery Directive are establishing stringent requirements for end-of-life management. Regulations are beginning to mandate minimum levels of recovered materials in new products and are implementing strict Extended Producer Responsibility schemes, wherein the original manufacturer is financially responsible for the recycling of their products. If a manufacturer chooses to assemble a battery pack with permanent adhesives that force expensive, hazardous, and low-yield recycling processes, they will bear the financial burden of those inefficiencies.

Simultaneously, the global Right to Repair movement is gaining immense legislative traction. Laws are being drafted that require consumer electronics manufacturers to provide repair manuals, spare parts, and, crucially, devices that can be opened and serviced without specialized, proprietary equipment. This directly targets the prevalent use of heavy adhesives in smartphones and laptops, forcing a return to modular designs secured by standardized, reversible mechanical fasteners.

Beyond legislation, the pure economics of raw materials are dictating a change in fastening strategies. As the global demand for lithium, cobalt, and rare earth elements outstrips supply, the value of the materials trapped inside end-of-life batteries and electronics is skyrocketing. The cost of designing a product for easy disassembly—including the added weight and cost of mechanical fasteners—is rapidly being eclipsed by the immense financial value of the high-purity materials that can be cleanly extracted at the end of its life.

11. Conclusion

The journey toward a sustainable, circular economy is paved with incredibly granular engineering decisions. While macroeconomic policies and advanced metallurgical recycling processes receive the bulk of public attention, the ultimate success of material recovery is decided on the assembly line. The choice between a drop of structural epoxy, a welded seam, or a specialized mechanical screw fundamentally dictates whether a complex electronic device or a massive automotive battery will be cleanly reborn into a new product or destructively relegated to toxic waste.

Design for Disassembly requires a holistic reimagining of product architecture. For consumer electronics, it means stepping back from the absolute limits of miniaturization to embrace snap-fits and standardized screws that enable robotic sorting and high-yield material recovery. For electric vehicles, it demands balancing the critical requirements of crash safety, thermal management, and lightweighting with the absolute necessity of non-destructive cell extraction. As technological innovation delivers active debonding adhesives and digitally traceable mechanical fasteners, the industry is gaining the tools necessary to bridge the gap between performance and circularity. Ultimately, the future of sustainable manufacturing depends on recognizing that the fasteners holding our technology together must also be designed to let it go.

Share This Story, Choose Your Platform!