High-Entropy Alloys for Extreme Aerospace Fasteners: A Performance Analysis Against Inconel 718

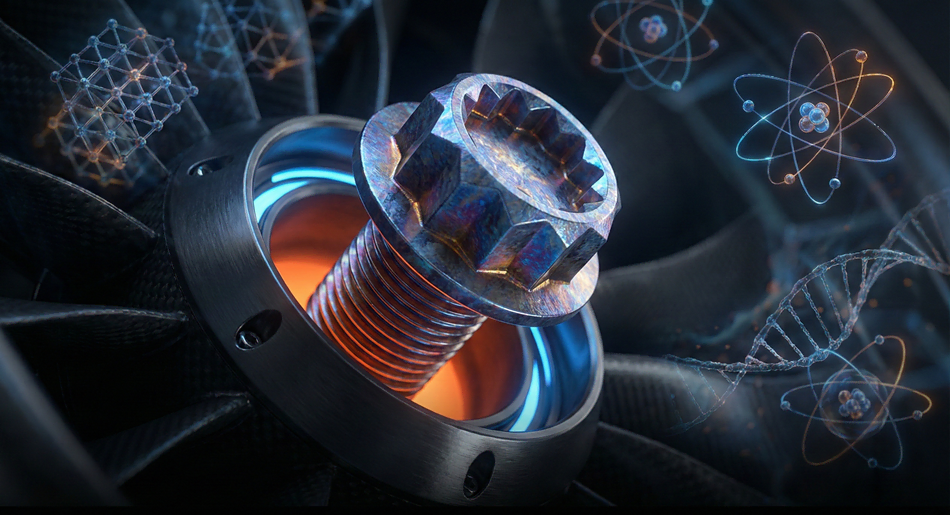

The aerospace industry is currently navigating a period of unprecedented propulsion advancement. As jet engines and rocket motors push toward higher bypass ratios and greater thermal efficiency, the materials used to hold these systems together are reaching their fundamental physical limits. At the heart of this challenge are aerospace fasteners. While often overlooked, these bolts, studs, and nuts must maintain clamping force at temperatures exceeding 700 degrees Celsius while resisting oxidation, creep, and fatigue. For decades, Inconel 718 has been the gold standard for these applications. However, the emergence of High-Entropy Alloys (HEAs) represents a paradigm shift that could redefine the structural integrity of next-generation flight hardware.

The Current Standard: Inconel 718 and the Nickel-Based Legacy

Inconel 718, a precipitation-hardened nickel-chromium alloy, has dominated the aerospace fastener market since its development. Its success is rooted in its unique microstructure, primarily the presence of gamma double prime and gamma prime precipitates. These phases provide exceptional yield strength and fatigue resistance up to approximately 650 degrees Celsius. In the current fleet of commercial and military aircraft, Inconel 718 fasteners are ubiquitous in the turbine assembly, exhaust systems, and high-pressure compressor sections.

Despite its pedigree, Inconel 718 suffers from a critical thermal ceiling. Beyond 650 degrees Celsius, the gamma double prime phase, which is responsible for much of its strength, begins to over-age or transform into the brittle delta phase. This microstructural instability leads to a rapid decline in mechanical properties. In modern “Hot Section” environments where temperatures frequently peak above 800 degrees Celsius, 718 fasteners are prone to stress-relaxation and creep-rupture, necessitating frequent inspection and replacement intervals that drive up the Total Cost of Ownership for airlines and defense operators.

The Genesis of High-Entropy Alloys

High-Entropy Alloys represent a departure from traditional metallurgy. Conventional alloys, like Inconel 718 or 316 Stainless Steel, are based on a single principal element (Nickel or Iron) with minor additions of other elements. HEAs, by contrast, consist of five or more elements in near-equimolar concentrations. This design philosophy utilizes high configurational entropy to stabilize a single-phase solid solution, typically a Face-Centered Cubic (FCC) or Body-Centered Cubic (BCC) lattice.

The theoretical foundation of HEAs is built upon the “Four Core Effects”: High Entropy, Sluggish Diffusion, Severe Lattice Distortion, and the Cocktail Effect. For aerospace fasteners, the sluggish diffusion effect is particularly vital. Because the atomic environment in an HEA is highly complex and disorganized, the movement of atoms (diffusion) is significantly slower than in conventional alloys. This translates directly to superior thermal stability; the microstructure resists coarsening and phase transformation even under prolonged exposure to extreme heat.

Mechanical Properties: The High-Temperature Battle

When comparing the mechanical performance of HEAs to Inconel 718, the distinction becomes most apparent at the thermal limits. At room temperature, a properly heat-treated Inconel 718 fastener can exhibit a yield strength exceeding 1,000 MPa. Many first-generation HEAs, such as the Cantor alloy (CoCrFeMnNi), show lower yield strengths at ambient temperatures but demonstrate remarkable strain-hardening capabilities and cryogenic toughness.

However, as the temperature scales toward 800 degrees Celsius, the narrative shifts. Research into refractory HEAs (RHEAs), which utilize elements like Tungsten, Molybdenum, Niobium, and Tantalum, has revealed alloys that maintain structural integrity at temperatures where Inconel 718 would essentially become plastic. These RHEAs maintain high hardness and strength due to their BCC structure and the inherent lattice distortion that hinders dislocation movement. For a fastener, this means the bolt can maintain its preload and prevent joint separation in environments that would cause a nickel-based superalloy bolt to stretch and fail.

Creep Resistance and Stress Relaxation

In aerospace fastening, creep resistance is arguably the most critical metric. Fasteners are subjected to a constant tensile load (the preload) at high temperatures. Over time, the material may undergo permanent deformation, or “creep,” which reduces the clamping force. If the clamping force drops below a critical threshold, the joint can leak, vibrate loose, or experience fatigue failure.

Inconel 718’s creep resistance is limited by the stability of its precipitates. Once the precipitates coarsen, the dislocations can bypass them more easily, leading to an accelerated creep rate. HEAs mitigate this through their unique atomic structure. The severe lattice distortion creates a “rugged” energy landscape for dislocations, making it difficult for them to climb or glide. Recent studies have shown that certain Al-Co-Cr-Fe-Ni HEA variants exhibit creep life spans that exceed Inconel 718 by several orders of magnitude at 750 degrees Celsius, suggesting that HEA fasteners could safely extend engine service life and maintenance cycles.

Thermal Stability and Oxidation

Fasteners in the turbine section are exposed to highly oxidizing environments. Inconel 718 relies on the formation of a chromium-oxide scale to protect the underlying metal. However, at extreme temperatures, this scale can become porous or spall off during thermal cycling. Many HEA systems are being designed with high concentrations of Aluminum and Chromium to promote the formation of complex, multi-element “protective skins” that are more adherent and stable than those found on traditional superalloys.

Furthermore, the thermal expansion coefficients of HEAs can be tuned by altering the elemental ratios. This is a massive advantage for aerospace engineers. By matching the thermal expansion of the HEA fastener to the expansion of the turbine casing it is securing, engineers can minimize the thermal stresses that occur during engine startup and shutdown, reducing the risk of fatigue-related cracking in the fastener threads or under the bolt head.

Manufacturing Challenges and Additive Solutions

One of the primary reasons Inconel 718 remains the industry workhorse is its manufacturability. It can be forged, rolled, and machined with relatively high efficiency. HEAs, especially refractory versions, are notoriously difficult to process. Their high melting points and the tendency of some constituent elements to segregate make traditional casting and forging a challenge. RHEAs are often brittle at room temperature, making the cold-heading process typically used for high-volume bolt production nearly impossible.

This has led to a synergy between HEAs and Additive Manufacturing (AM). Laser Powder Bed Fusion (LPBF) allows for the production of HEA fasteners with complex geometries that would be unachievable through traditional machining. AM also provides the rapid cooling rates necessary to suppress the formation of unwanted intermetallic phases, ensuring a homogenous, high-performance microstructure. For low-volume, high-value components like space launch vehicle fasteners, AM HEAs are already becoming a viable alternative to CNC-machined Inconel 718.

Environmental and Economic Implications

The shift toward HEAs is not merely a matter of performance; it is a matter of sustainability and resource management. Inconel 718 is heavily dependent on Nickel and Niobium, metals that have experienced significant price volatility. HEAs offer the “Cocktail Effect,” allowing metallurgists to swap out expensive or scarce elements for more abundant ones without sacrificing performance. By optimizing the entropy of the system, researchers can create high-performance alloys using more sustainable elemental palettes.

From an operational perspective, the transition to HEA fasteners represents a “set and forget” strategy for engine manufacturers. If a fastener can last the entire life of a turbine without requiring replacement, the reduction in downtime and labor costs for airlines would be substantial. This aligns with the long-term goals of aerospace leaders who are seeking to reduce the environmental footprint of aviation through higher operating temperatures and better fuel efficiency.

Comparison Table: Inconel 718 vs. High-Entropy Alloys

| Property | Inconel 718 (Standard) | Refractory HEAs (Emerging) |

|---|---|---|

| Principal Lattice | FCC (Gamma Matrix) | BCC or FCC (Configurational) |

| Maximum Service Temp | 650°C – 700°C | 800°C – 1200°C+ |

| Strengthening Mechanism | Precipitation (Gamma” / Gamma’) | Solid Solution / Sluggish Diffusion |

| Creep Resistance | Moderate; degrades > 650°C | High; stable at extreme heat |

| Thermal Stability | Phase transformation at heat | Exceptional phase stability |

| Manufacturability | High (Forging/Machining) | Moderate (Requires AM/PM) |

Future Directions: AI and Computational Design

The sheer number of possible elemental combinations in the HEA space—estimated in the millions—makes traditional “trial and error” metallurgy obsolete. The future of HEA fasteners lies in Integrated Computational Materials Engineering (ICME). Machine learning algorithms and density functional theory (DFT) are being used to predict the stability and mechanical properties of HEA compositions before a single gram of metal is melted.

This computational approach is allowing researchers to design “functionally graded” fasteners. Imagine a bolt where the head is optimized for high fatigue resistance and the threaded shank is optimized for maximum creep resistance. By varying the HEA composition throughout the part using multi-material additive manufacturing, the next generation of fasteners will be tailored to the specific stress and temperature gradients of their application.

Conclusion

The transition from Inconel 718 to High-Entropy Alloys in aerospace fasteners is not a question of “if,” but “when.” As the aerospace industry strives for greater thermal efficiency, the limitations of nickel-based superalloys become more apparent. HEAs offer a solution that bypasses the traditional trade-offs between strength and thermal stability. While manufacturing and cost hurdles remain, the superior creep resistance, oxidation performance, and potential for custom design make HEAs the clear successor for extreme environment hardware. For industry giants and maintenance providers alike, the adoption of HEA technology will be the key to unlocking the next frontier of high-performance propulsion.

Share This Story, Choose Your Platform!